Punahelu(puna, make) he mea hana kūikawā i hoʻohana ʻia i nā hana a ke kanaka. Hoʻopili ka papa helu punahelu i kahi laulā. I ke kaiāulu o kēia au, pili pili ka mea kahiko i ka hana ʻenehana, kahi e hoʻomaikaʻi nui ai i ka hana ʻana a me ka pololei o nā ʻāpana.

ʻO ka puna he mea hana kūikawā i hoʻohana ʻia i nā hana a ke kanaka. Hoʻopili ka papa helu punahelu i kahi laulā. I ke kaiāulu o kēia manawa, pili ka mould i ka hana ʻenehana, kahi e hoʻomaikaʻi nui ai i ka hana ʻana a me ka pololei o nā ʻāpana.

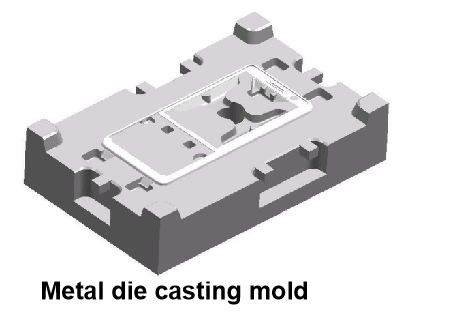

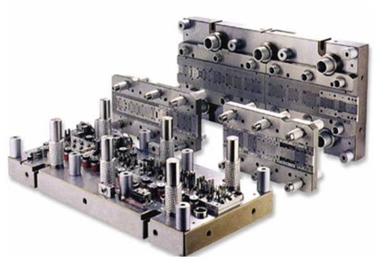

ʻO ka mould ka mea hana ʻenehana e hoʻohālikelike i (kinohinohi) i nā huahana a me nā ʻāpana me nā kiko kikoʻī a me nā nui. Me ka: hahi ʻana i ka make, ka popopo hoʻoheheʻe palaka, make hoʻoheheʻe puna, forging punahelu, pauka metallurgy make punahelu, drawing die, extrusion die, ʻolokaʻa make, aniani make, laholio punahelu, pālolo punahelu, hoʻolei punahelu a me nā ʻano ʻē aʻe. I ka ʻoihana hou, pili ka punahelu i ka punahelu i hoʻohana ʻia i ka hana nui o nā ʻāpana palaka a me nā ʻāpana lako pono. Ke hoʻohana ʻia ia e hana i kahi mea paʻa mai ka palekiko wai, nā mea hao a me nā mea ʻē aʻe i injected i loko o kāna lua, kapa mākou iā ia he "puna" a i ʻole "puna". Ke hoʻohana ʻia ia no ke kuʻi ʻana, kūlou, kūlou a extrusion o ka blank blank, kāhea pinepine mākou iā ia he "make".

Hoʻokaʻawale ʻia ka punahelu e kāna mau hiʻohiʻona e like me kēia:

Classification o ka hopena he

Hoʻohui ʻia e nā ʻenehana a me nā ʻenehana hana, hiki ke hoʻokaʻawale ʻia nā moʻo i nā punaewele make make, palolo palolo a me nā punahele kūikawā. (1) Mould non-metallic and powder metallurgical molds: plastic molds, sinter molds, one molds, vacuum molds and paraffin molds. Me ka hoʻomohala wikiwiki o nā plastics polymer, pili pili nā palolo palaka i ko ke ola mau kānaka. Hiki ke mahele pinepine ʻia nā kinikini lula i: nā hopena hoʻoheheʻe, nā puna extrusion, nā mōlina kōkua kinoea, a pēlā aku

(2) Māhele ʻia ka make o nā lakohana i loko: make casting casting, stamping dies (e like me ka make ʻana i ka punch, make i ke kūlou, make i ke kiʻi ʻana, make i ka make, make i ka make. e like me ka make forging ʻana, make hoʻi i ka huhū, a pēlā aku.), make nā mea extrusion, make casting, make forging, etc.

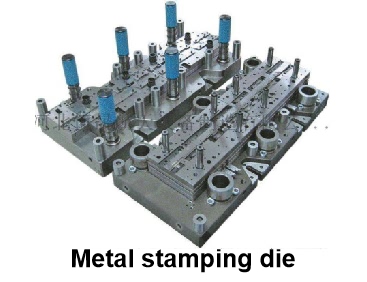

Make hahi hao

1. Classification o ea punahelu

(1) ʻumekau punahelu ka pahu kui mōlina mea he ano o ka punahelu hoʻohana no ka ho okumu ana i na hapa o thermoplastic a me thermosetting lula. Hoʻohana ākea ka hoʻopili ʻana no ka mea he kiʻekiʻe kikoʻī a me ka maikaʻi.

Hoʻokomo ka hoʻoheheʻe ʻana e hoʻohui i ka ea i loko o ka pahu hoʻomehana o ka mīkini hoʻokomo. Hoʻomehana a hoʻoheheʻe ʻia ka plastic. Kipaku ʻia e ka ʻāʻī a i ʻole ka plunger o ka mīkini hoʻokomo, ua hoʻokomo ʻia nā plastic i loko o ka lua o ka punahelu ma o ka nīʻī a me ka ʻōnaehana ninini ninini, a paʻakikī a ʻano i loko o nā huahana hoʻoheheʻe ma muli o nā hana kino a me nā kemika. ʻO ka hoʻoheheʻe ʻana he paukū ia e hoʻopili ana, e hoʻopaʻa ana i ke kaomi (hoʻomaha) a me ke kaʻina hana demoulding o nā ʻāpana lula. No laila, he mau manawa kūlohelohe ka hoʻoheheʻe ʻana.

Thermoplastic ka pahu kui mōlina i ka pono o pōkole mōlina pōʻaiapuni, kiʻekiʻe? Iecaianoaaiiie ka hoʻokōʻana, uuku Wear o nā mea hoʻoheheʻe ma ka punahelu, a me ka nui o ka ea wahi me ka luna 'kinona, mōakāka luna lauana a me ka mark, a me kiʻekiʻe dimensional pololei. Eia nō naʻe, no nā ʻāpana palika me ka loli o ka mānoanoa o ka paia, paʻakikī e pale i nā hemahema mōlina. ʻO ka Anisotropy o nā ʻāpana plastik kekahi o nā pilikia maikaʻi. Pono e hana i nā ana kūpono āpau e hoʻoliʻiliʻi.

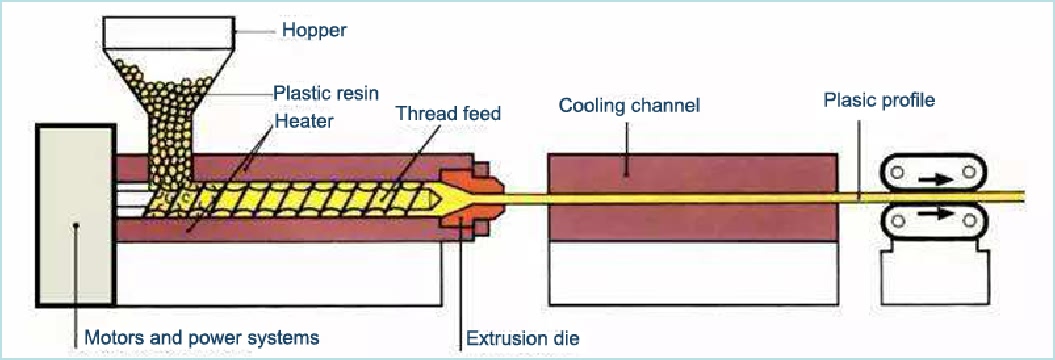

Punahelu hoʻouka

(2) Moʻomanaʻo extrusion no ka palakiko Palekana extrusion moʻo kahi ʻano hana e hana ai i ka ea i ka mokuʻāina viscous e hele i loko o ka make me kahi ʻano ʻāpana ʻāpana i ka mahana kiʻekiʻe a me kekahi kaomi, a laila hoʻohālikelike ʻia ia i ka ʻike hoʻomau me koi 'ia nā māhele o ke kuea ma ka mahana haʻahaʻa. ʻO ka hana hana o extrusion moulding ka hoʻomākaukau o nā mea hoʻoheheʻe mea, extrusion mōlina, anuanu hoʻonoho, traction a me ka ʻoki, kia-aaioee o extruded huahana (hoʻoikaika kino a me ka hana wela). I ke kaʻina o ka extrusion, pono e nānā i ka hoʻoponopono ʻana i ka mahana, ka wikiwiki o ka wikiwiki a me ka wikiwiki traction o kēlā me kēia ʻāpana hoʻomehana o ka barela a make i ka extruder i mea e loaʻa ai ka ʻike extrusion. Pono e uku ʻia ka nānā kūikawā i ka hoʻoponopono ʻana i ka helu extrusion o ka hoʻoheheʻe ʻana o polymer mai ka make. Ma muli o ka haʻahaʻa o ka helu extrusion o nā mea hoʻoheheʻe ʻia, he pae laulā ka extrudate a me ke ʻano o ka ʻāpana ʻāpana, akā i ka hiki ʻana o ka extrusion rate o ka mea hoʻoheheʻe ʻia i kekahi palena, e lilo ka ʻaoʻao extrudate i mea ʻino a lilo i ka ʻālohilohi, a me ka ʻili manō. e ʻike ʻia ka ihi ʻalani, ke ʻano o ka distortion a me nā phenomena ʻē aʻe. Ke piʻi aʻe ka nui o ka extrusion, e kekeʻe ka ʻili o ka extrudate, a ʻo ka lālā a haki hoʻi i nā ʻāpana hoʻoheheʻe a i ʻole nā paukū ʻolokaʻa. No laila, he mea nui ka kaohi o ka helu extrusion.

Make make loa

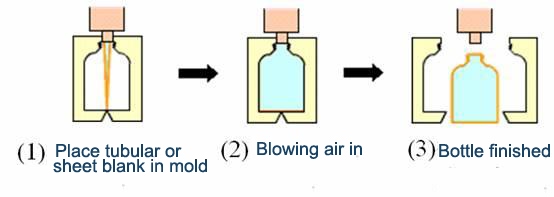

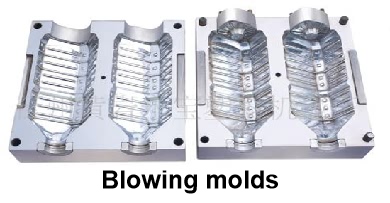

(3) Hollow hana mould

Ke hollow ho okumu i nā extrusion pahi mōlina hollow ho okumu ana a me ka pahu kui puhi mōlina hollow ho okumu i elua ano o ka hopena he.

ʻO ka hollow molding kahi ʻano hana hana e hoʻoponopono i ka tubular a i ʻole ka pepa hakahaka i hana ʻia e ka extrusion a i ʻole ka injection a i loko nō ia o ke kūlana plasticizing i ka hoʻoheheʻe ʻana, e hoʻokomo koke i ka ea compressed, e hoʻokau i ka hakahaka e hoʻonui a pili i ka paia o ka lua mould, a me demould ma hope o anuanu a me ka finalizing, i mea e loaʻa ai ke koi hollow huahana.

ʻO nā lula e kūpono no ka hollow molding he polyethylene kiʻekiʻe, haʻahaʻa polyethylene haʻahaʻa, polyvinyl chloride paʻa, polyvinyl chloride palupalu, polystyrene, polypropylene, polycarbonate, a me nā mea ʻē aʻe e like me nā ʻano hana like ʻole o ka pālona, hiki ke hoʻokaʻawale ʻia ka hollow i extrusion blow molding a hoʻoheheʻe puhi mōlina. ʻO ka pōmaikaʻi o ka extrusion blow molding hollow e hana ana he maʻalahi ka hanana o extruder a me extrusion blow molds. ʻO ka hemahema ke kūlike ʻole o ka mānoanoa o ka paia o ka parison, kahi e maʻalahi ai ka mānoanoa o ka paia o nā huahana lula. ʻO ke kiʻi kūpono ke kiʻikuhi hoʻolālā o ka extrusion blow molding hollow e hoʻokumu ana i ka rula.

ʻO ka pōmaikaʻi o ka hoʻoheheʻe ʻana i ka pupuhi ka maikaʻi o ka mānoanoa o ka paia a ʻaʻohe kaʻe lele. Ma muli o ka lalo o ka hana hoʻoheheʻe, ʻaʻole hana ka lalo o ka hollow huahana i ka seam splicing, ʻaʻole ia he mea nani akā ka ikaika kiʻekiʻe kekahi. ʻO ka maikaʻi ʻole o nā lakohana a me nā punahelu i hoʻohana nui ʻia, no laila hoʻohana nui ʻia kēia ʻano hana i ka hana nui o nā huahana hollow liʻiliʻi, a hoʻohana ʻole ʻia ia i ka hoʻohana ʻana o extrusion blow molding hollow form method.

Ka pahu kui puhi no ka lula

Pā palapū

(4) Nā mea hoʻoheheʻe make no ka plastic

ʻO nā mea hoʻoheheʻe make e kapa ʻia nā moʻo hoʻoili. Hoʻohui ʻia ka mea ea i loko o ke keʻena hānai preheated, a laila hoʻokomo ʻia kaomi i ke kolamu kaomi. E hoʻoheheʻe ka plastic ma lalo o ke kiʻekiʻe o ka mahana a me ke kaomi, a komo i loko o ka lua ma o ka ʻōnaehana hoʻoheheʻe o ka puna, e hoʻoliʻiliʻi a hana hoʻi. Kapa ʻia kēia hana hana i kapa ʻia ka make-casting, a kapa ʻia ka punahelu i kapa ʻia ka make-casting. Hoʻohana ʻia kēia ʻano moʻa no ka thermosetting ea e hana ana.

(5) Mīkini hoʻopili

Mīkiniʻopihia mōlina o kekahi o ka loiloi mua mōlina hana o ea ea. Hoʻopili ka hoʻopili ʻana e hoʻohui pololei i nā lula i loko o ka lua o ka make me kahi mahana, a laila pani ka make. Ma lalo o ka hana o ka wela a me ke kaomi, hoʻoheheʻe ka plastic i kahi moku kahe. Ma muli o ka hana kino a me nā hana kemika, paʻakikī ka Plastics i nā ʻāpana plastic me kekahi ʻano a me ka nui ma ka mahana o ka lumi. Hoʻohana nui ʻia ka mīkini hoʻowalewale i ka hoʻoheheʻe ʻana i nā ea thermosetting, e like me ka paukū phenolic mōlina, urea formaldehyde a me melamine formaldehyde mōlina paukū, aniani puluniu hoʻoikaika ʻia phenolic lula, epoxy kēpau, DAP kēpau, mea pīlali kēpau, polyimide a pēlā aku. Hiki iā ia ke hoʻoheheʻe a me ka hana ʻana i nā hōʻuluʻulu polyester unsaturated (DMC), nā mea hoʻoheheʻe pepa (SMC), prefabrication. ʻO nā plastics mōlina monolithic (BMC) a pēlā aku. ʻO ka maʻamau, kaomi pinepine ʻia ke ʻano hoʻohālikelike o ka make o luna a me lalo o ke kiʻi hoʻoliʻiliʻi, a hoʻokaʻawale ʻia ka make o ka compression i ʻekolu mau ʻano: ʻano overflow, ʻano non-overflow a me ʻano semi-overflow.

(6) Make ka hoʻolei kaomi

ʻIke pū ʻia me ka hoʻolei make ʻana. Hoʻohui ʻia ka mea ea i loko o ke keʻena ukiuki preheated, a laila hoʻokomo ʻia ke kolamu kaomi i loko o ke keʻena e hoʻopiʻi ana e laka i ka make. Hoʻokomo ʻia ke kaomi i ka ea ma o ka kolamu kaomi. E hoʻoheheʻe ka plastic i kahi moku e kahe ana ma ke kiʻekiʻe o ka mahana a me ke kiʻekiʻe, a paʻa i loko o ka lua i ka ʻōnaehana ninini. Kāhea ʻia kēia hana hana i kapa ʻia ka hoʻoili hoʻoili. Kūpono ka hoʻoheheʻe puʻe no ka lula paʻa me nā helu hoʻoheheʻe like ʻole. I ke kumu, hiki ke hoʻohana ʻia no ka hoʻoheheʻe ʻana a me ka hoʻoheheʻe ʻana i ka ʻomi puʻe. Eia naʻe, ke haʻahaʻa ka mahana paʻa ma mua o ka mahana paʻa, maikaʻi ka wai o ka hoʻoheheʻe, a ke kiʻekiʻe ka mahana paʻa, ʻoi aku ka kiʻekiʻe o ka paʻa.

2. Make ka hoʻonohonoho ʻana i nā lako pono

Wahi a nā pono hana a me ke kaʻina hana, hiki ke hoʻokaʻawale ʻia ka hoʻoheheʻe hao i nā puna hana wela a me nā puna anuanu. Nui ka ʻokoʻa ma waena o lākou

1) make hana wela: pili ke kila hana kila i ka make kūpono no ka deformation wela o ka hao, e like me ka make extrusion wela, make make make, make for hot, make wela wela, a me nā mea ʻē aʻe e like me ka make ʻana o ka hana wela ma lalo o ke kiʻekiʻe wela. a me ke kiʻekiʻe kiʻekiʻe no ka manawa lōʻihi, koi ʻia ka mea make i loaʻa ka ikaika kiʻekiʻe, paʻakikī a me ka paʻa paʻa, ʻoi loa ka ikaika wela, luhi wela, paʻakikī a ʻaʻa pale. Hoʻohui nui ʻia:

A. Metal make e hoʻolei ana i ka punahelu make: ʻo ke kaʻina e hoʻopili i nā mea hoʻoheheʻe wai hoʻoheheʻe ʻia i loko o ka lua make e loaʻa nā ʻāpana kūkulu i koi ʻia. Hoʻohana ʻia ka hana hoʻoheheʻe metala e hana i nā ʻāpana ʻano paʻakikī o ke kinikini aluminika, kinikini kinikini, a me nā kinipona magnesium a me nā mea hao non-ferrous ʻē aʻe.

B. ʻO ka paukū paʻakai sinter puna: ʻo ke kaʻina e hana i ka pauka metala i kahi ʻano a me ka nui o ka bila i loko o ka popopo, a laila hoʻomehana i ka bila i ka pae hoʻoheheʻe, i hiki ai ke hana. Hoʻohana nui ʻia ka paukū paukū kuni no ka kila kila, titanium, keleawe, hao, nickel a me nā ʻāpana o ke anuanu kiʻekiʻe.

C. Metal wela extrusion make: wela hana wela extrusion make pili pono i ka hana ʻana o ka aluminika, magnesium, kila a me nā mea hao ʻē aʻe i kahi kiʻekiʻe o ke ana wela, a ʻaʻole i loli ke ʻano o ke kuea o nā ʻāpana i hana ʻia. Koi ʻia ka make extrusion wela e loaʻa i ke kūpaʻa ʻaʻano wela-hoʻopale maikaʻi a me ke kūpaʻa tempering.

2) Make ka hana anuanu (make Stamping): make ka hana anuanu i ka hana ʻana i ka mahana o ka lumi, i kapa ʻia he stamping dies (e like me ka make ʻana o ke kuʻi ʻana, make ke kūlou, make ʻana, make ʻana, hāʻule nā wai, make a ʻōwili ʻia, make ʻōhū ʻia. , make make, a pēlā aku). Pono ka ʻāpana hana o ke anuanu e hana i ke kaomi, ke kūlou ʻana, ka ikaika a me ka ikaika o ka friction, no laila he nui ka pale deformation.

A. Make blanking metala: hoʻohana ʻia ka make blanking metala e ʻokiʻoki i ʻelua dimensional mai ka pā metala. Hiki ke hoʻohana ʻia i nā ʻāpana e like me ka hakahaka no ke kūlou ʻana, ke kaha kiʻi ʻana a me ke kūkulu ʻana. Hoʻohana nui ʻia ka Blanking no ka hakahaka ʻana, ke kuʻi ʻana a me ka hōʻoki ʻana i ke kila, ke kila kila, ke kinikini aluminika, ke kinikini keleawe a me nā pā ʻē aʻe.

B. Kūlou make: kahi ʻāpana e hoʻohana ai i ka make e pelu i nā pā, nā kī a me nā ʻāpana i kekahi kihi, ka piʻo a me ke ʻano. Kūpono ia no ke kila, ke kila kila, ke kinikini aluminika a me nā ʻāpana kūmole keleawe.

C. Drawing die: ʻo ke kaha kiʻi ke kaʻina o ka hahi ʻana, ke kaha ʻana i ke apo a i ʻole ka make mea hoʻoheheʻe e hoʻololi i nā mea metala pepa i ka paukū a i ʻole nā ʻāpana ʻano pahu. ʻO ke kaha kiʻi ʻana he mea hana maʻamau ia no ke kaha kiʻi ʻana.

D. make make: ʻo ka hoʻohana ʻana i ka make form kahi ʻano hana hana e lawe ʻia ai ka deformation ea ma kahi paʻa ʻoiai ʻaʻole e loli kona ʻano a me nā ʻano pono.

E. Make ʻo Riveting: he riveting metala kahi hana o ka hoʻopili ʻana i ʻelua mau mea hana ma waena o nā mea hana waena e ka ikaika mechanical. ʻO ka maʻamau, hoʻohana ʻia ka riveting ma waena o nā pā pālahalaha. Kāhea ʻia ka make i ke kaʻina ʻo riveting die.

Noi o ka hopena he make paha:

(1). Nā huahana uila a me nā kamaʻilio:

(2). Nā pono hana o ke keʻena;

(3). ʻO nā ʻāpana kaʻa kaʻa:

(4). Nā mīkini home

(5). Nā pono uila:

(6). Palekana olakino a me nā hana kaiapuni:

(7). Nā ʻenehana hana;

(8). ʻIke kuʻi;

(9). Kaʻa halihali;

(10). Nā lako hana, ka lumi kuke a me nā pono pono a me nā pono hana

He mea hana ʻo Mestech i ka hana hana hoʻoheheʻe a me ka hana hoʻoheheʻe no kahi o 10 mau makahiki. Mākou i maikaʻi ʻenekini kime a me ka waiwai manufacturing hana. Hiki iā mākou ke hoʻolālā a hana i ka mōlina hoʻowalewale paleki kūlana kiʻekiʻe no kā mākou mea kūʻai aku. Uhi kā mākou mōlina hoʻohelu uhi uila, uila, kaʻa, 'inikua, halihali a me nā pono hana. Inā makemake ʻoe, e ʻoluʻolu e leka uila iā mākou.