Mould (puna) a make he mau pono hana e hana i ka hakahaka a i ʻole ka mea maka i nā ʻāpana me ke kiko kiko a me ka nui ma lalo o ka hana o ka ikaika kūwaho. Hoʻokomo ʻia kēia mea hana i nā ʻāpana like ʻole, a haku ʻia nā punahelu ʻokoʻa i nā ʻāpana like ʻole. ʻO ke kaʻina hana e hoʻololi nui i ke kūlana kino o nā mea e loaʻa ai ke kinona o ka mea. ʻO ka pala a make hoʻi nā pono hana no ka hana nuipaʻa. Hoʻonui maikaʻi ka noi o ka popopo i ka hana pono a me ka hana hou ʻana o nā ʻāpana. ʻIke ʻia ʻo ia ka "makuahine o ka ʻoihana".

Hiki ke mahele ʻia ka punahelu a me ka make i ʻelua mau ʻāpana e like me kā lākou ʻano hana

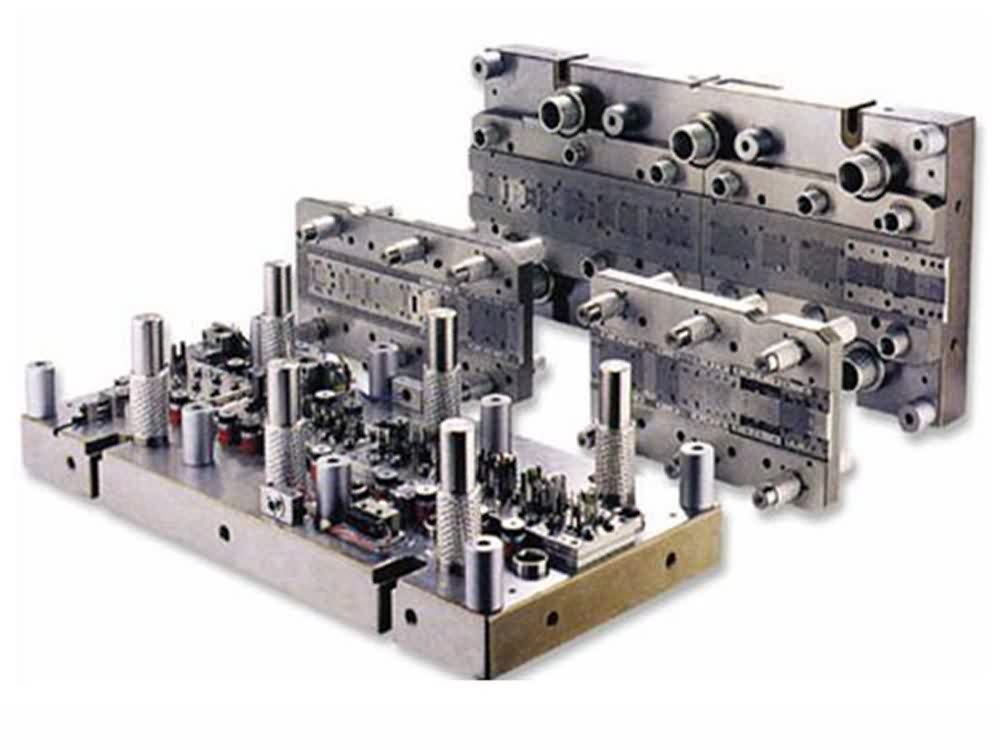

1. Make: hiki i ka noi o ke aniani kinohi ke hana i ka hoʻokaʻawale hakahaka paʻa (blanking) e like me ke ʻano o ka contour, a i ʻole ke kūlou extrusion mōlina. Hoʻohana ʻia kēia ʻano make no ka hakahaka ʻana, ka make ʻana, ke poʻo anuanu a me ka extrusion o nā ʻāpana.

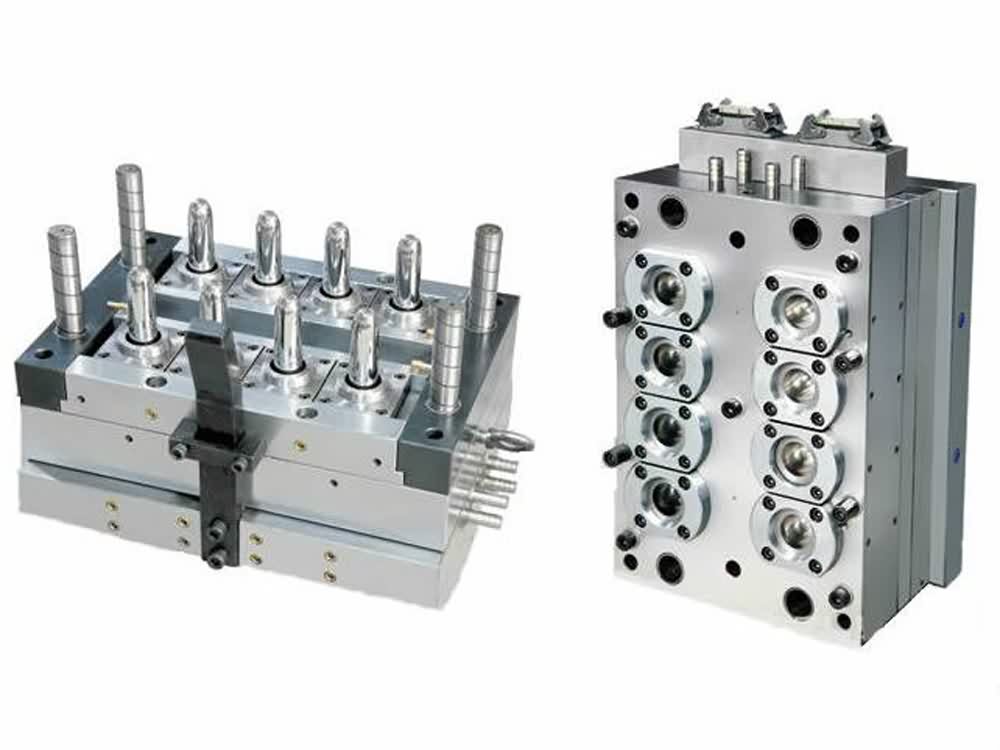

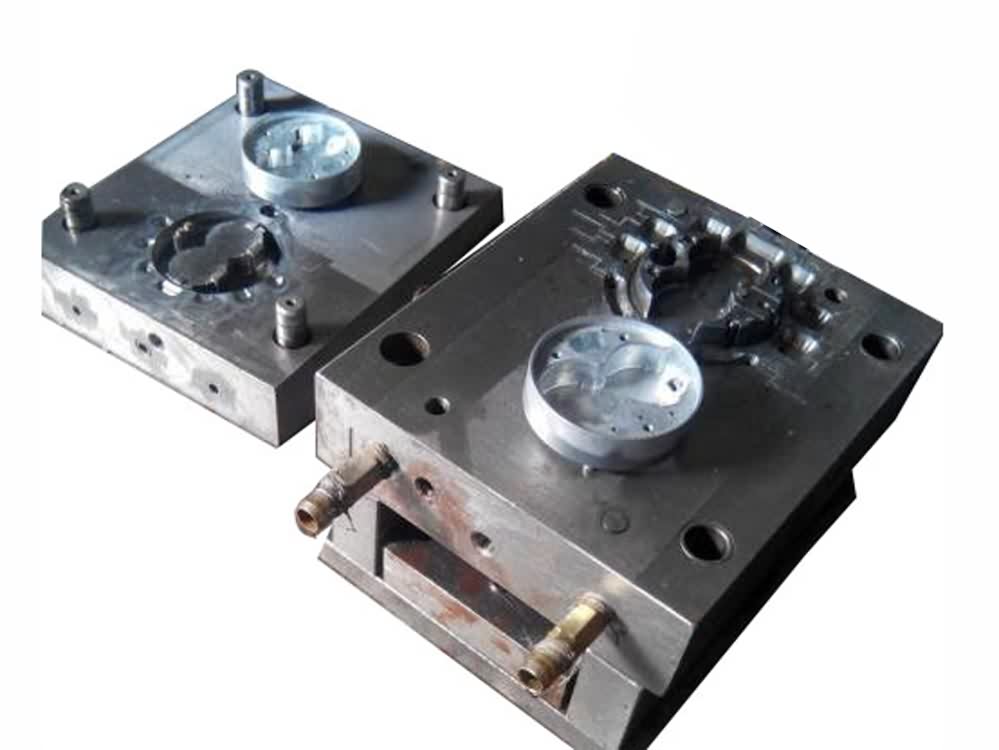

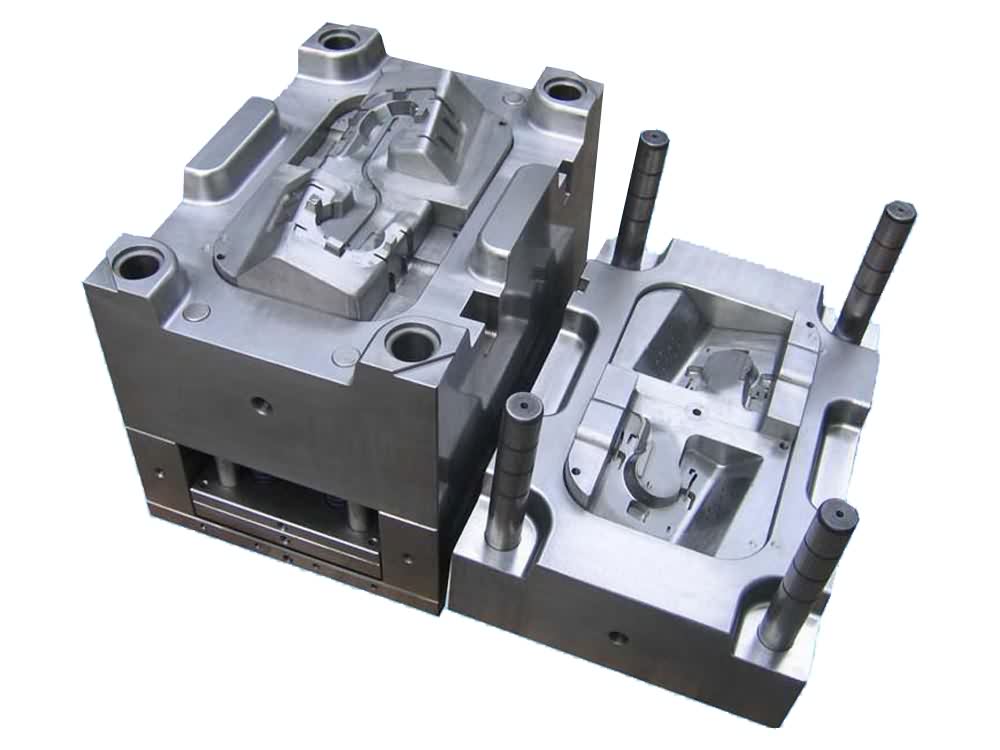

2. Mould: hoʻopili ʻia nā mea colloidal a wai paha i loko o ka lua mould, a i ʻole hoʻoheheʻe ʻia nā mea paʻa i ka lua o ka punahelu, hoʻopihapiha a hoʻoluʻolu e kiʻi i nā huahana me ke ʻano like me ka ʻāpana puna. Hoʻohana ʻia kēia ʻano mōlina i nā ʻāpana palaka i hoʻoheheʻe ʻia, silica gel molding, metal die casting. ʻO ka maʻamau ma waho o kahi maʻamau, hoʻokaʻawale mākou i nā make no nā metala hao ʻole e like me ke kinikini aluminika a me nā kinikini zinc e like me ka make

Palapala hoʻohewa lula

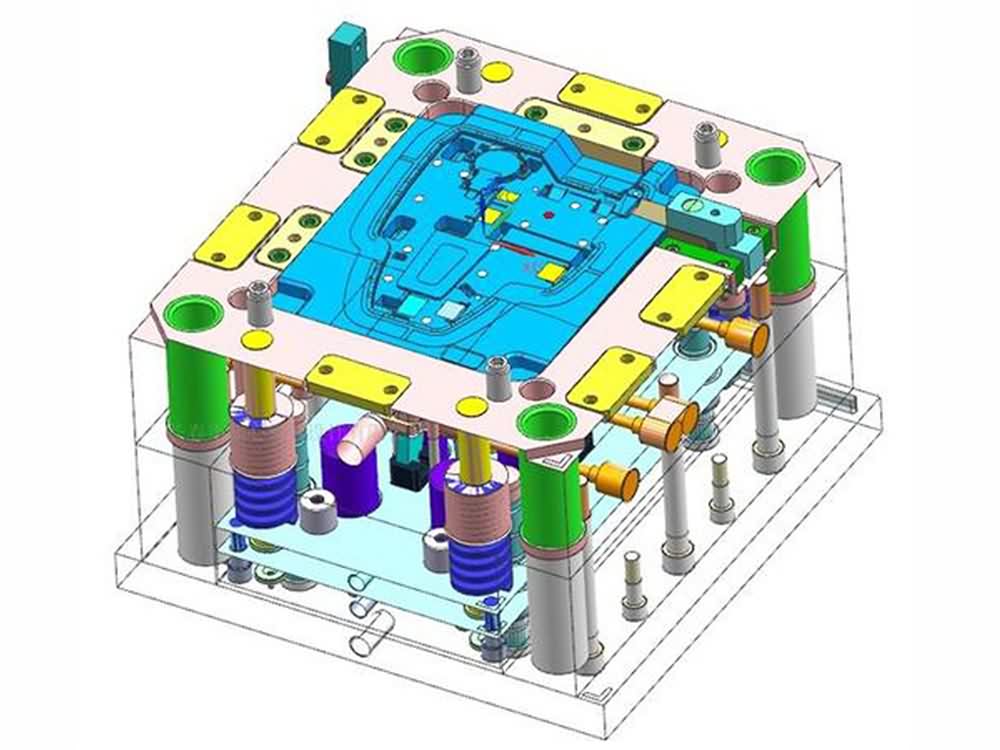

Hoʻolālā punahelu

Moʻomoʻo kukini wela

Hoʻokomo mōlina

Pālua hoʻoheheʻe mōlina

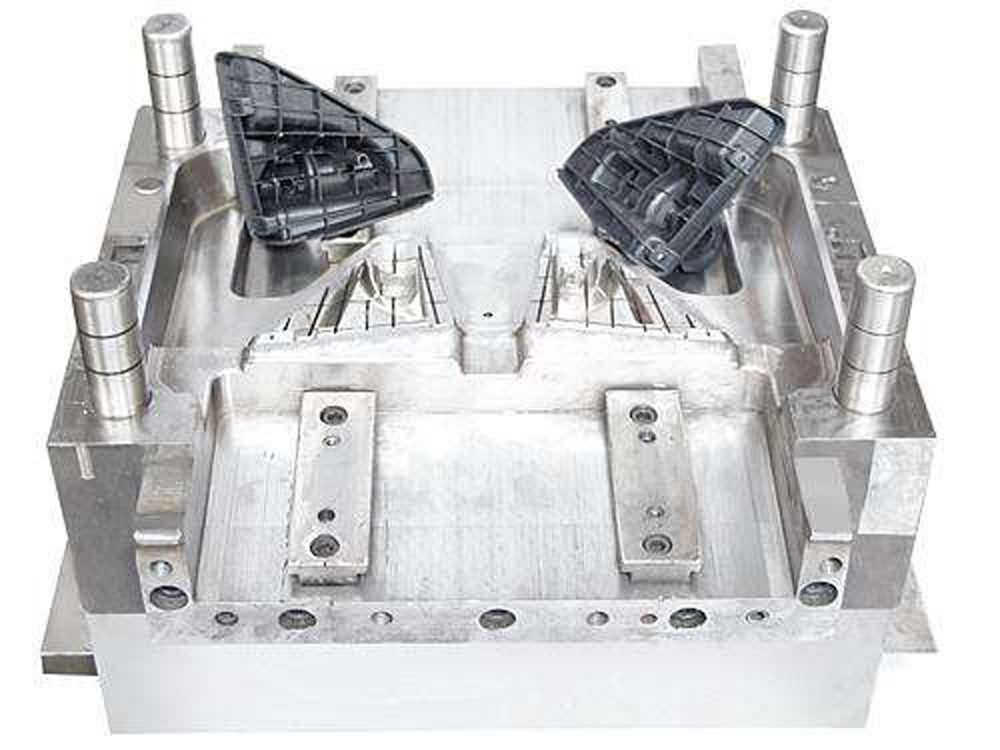

Ka hopena o ka pahu kui no nā ʻāpana kaʻa

Nā kinikini silikona

Make hoʻoheheʻe mōlina

Nā mea hoʻoheheʻe hao

HASCO nā pahu kui

Wahi a nā kumuwaiwai o nā huahana i hana ʻia ma o ka pala, ua māhele ʻia ka punahelu i:

mea hoʻoheheʻe keleawe, palolo palolo, a me punahelu pecial.

1. Mould punahelu: me ka hahi ʻana make (e like me ka hakahaka make, kūlou make, kahakaha ʻana make, flanging make, shrinkage make, undoting make, bulging make, hoʻomoe kinoea, etc.), forging make (e like me make forging make, hoʻonāukiuki make , etc.), extrusion make, make casting make, forging make, a pēlā aku.

2.Nonmetal punahelu ua mahele ʻia i: ea punahelu, inorganic non-mea hao punahelu, one punahelu, holo punahelu a me ka paraffin punahelu. Ma waena o lākou, me ka hoʻomohala wikiwiki ʻana o nā plastics polymer, pili pono ka palolo palaka i ke ola o ka poʻe. Hiki ke mahele pinepine ʻia ka palolo palapū i: ka hoʻoheheʻe mōlina, extrusion mōlina punahelu, kinoea kōkua mōlina mōlina, a pela aku

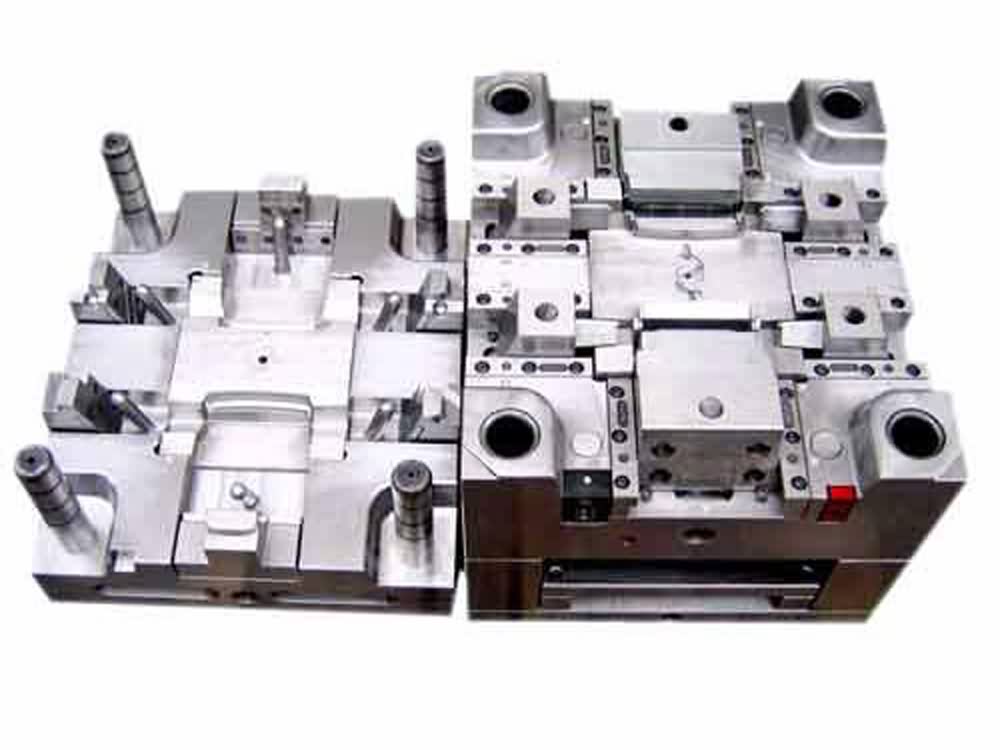

Loaʻa i ka mould a me ka make i kahi contour kikoʻī a i ʻole ke ana lua, a hiki ke hoʻokaʻawale ʻia ka hakahaka (blanking) e like me ke ʻano o ka contour me ka hoʻohana ʻana i ke ʻano contour me ka lihi I ka hoʻohana ʻana i ke kinona o ka lua o loko, hiki i ka hakahaka ke kiʻi i ke kinona ʻekolu dimensional. ʻO ka make he ʻelua mau ʻāpana: neʻe make a paʻa paʻa (a i ʻole punch a make), hiki ke hoʻokaʻawale a pani ʻia. Lawe ʻia nā ʻāpana i ka wā e kaʻawale ai, a hoʻokomo ʻia ka hakahaka i ka lua make no ka hana ʻana ke pani ʻia.

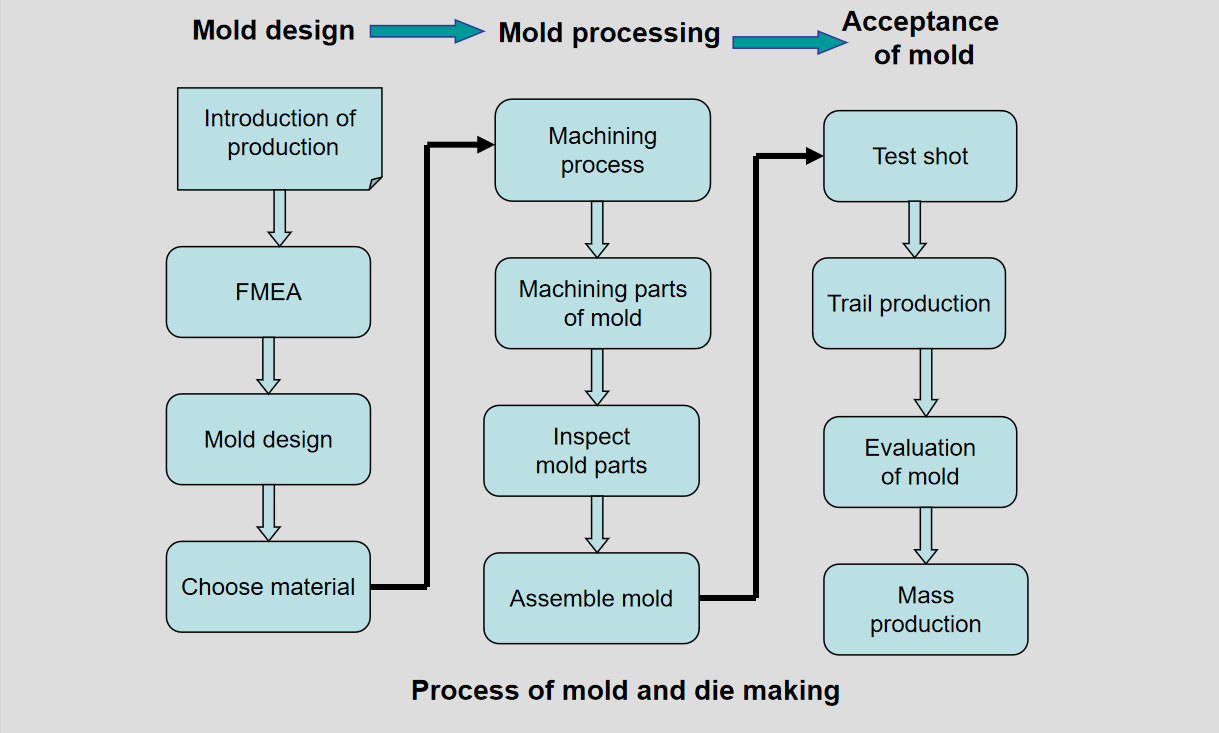

Aia he ʻekolu mau anuu i ka hana ʻana o ka punahelu: 1.Mold design; 2.mehana hana; 3. ʻAe o ka punahelu

Hāʻawi ʻo Mestech i nā mea kūʻai aku me ka hoʻolālā o nā ʻāpana palika a me nā ʻāpana metala, ka hana ʻana i ka popopo hoʻoheheʻe, make hoʻoheheʻe hoʻoheheʻe a me ka puna blanking A me ka hoʻohana ʻana o nā popopo no ka hana nuipaʻa o nā ʻāpana lula, nā ʻāpana kila. Ke kakali nei mākou i ka hana pū ʻana me ʻoe e hāʻawi iā ʻoe i ka hana ʻana i ka popopo a me nā ea, nā ʻāpana metala a me nā lawelawe.